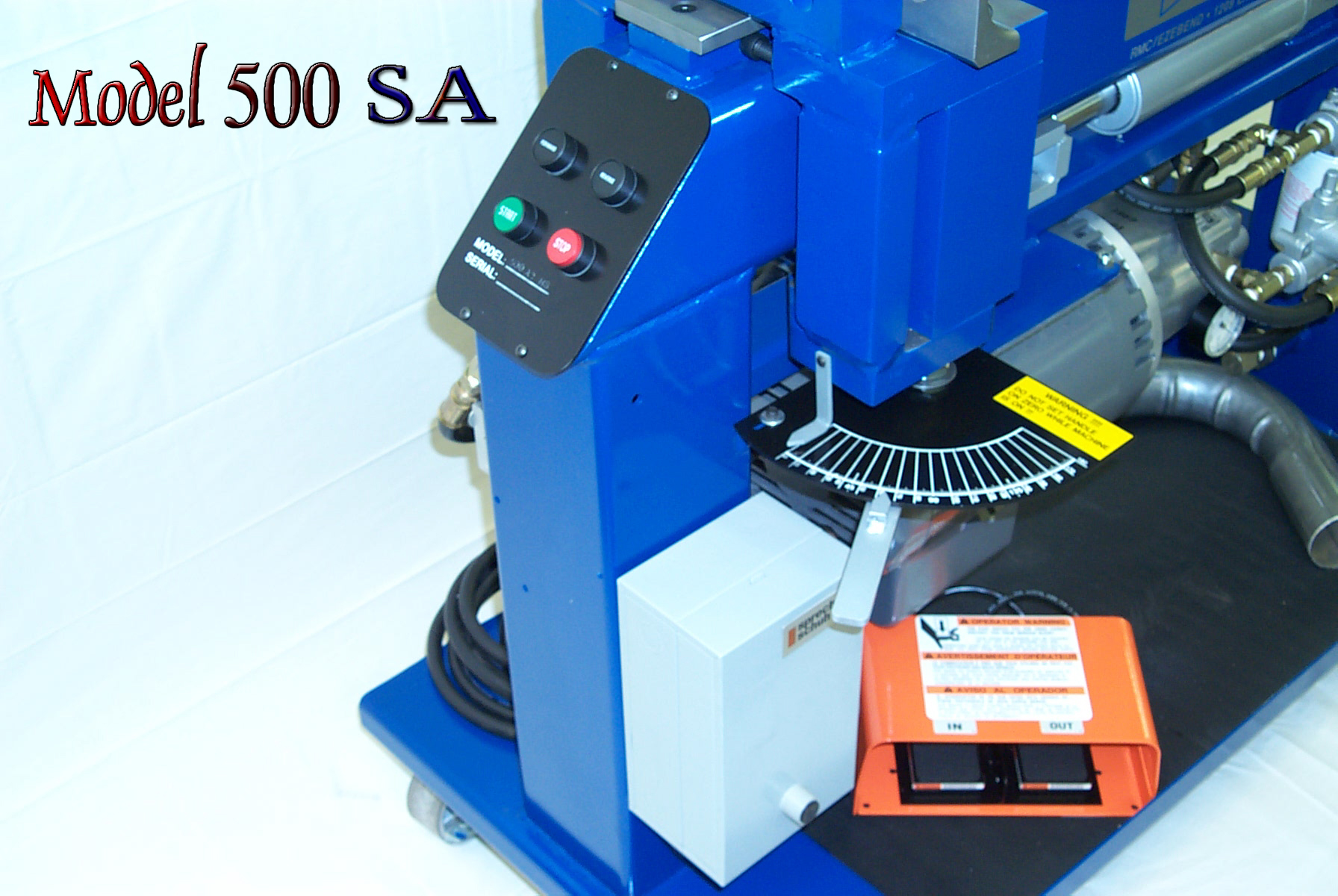

This is a

full-size, bend only, tube bender without end forming. This

EZEBEND™

Tube Bender comes with Semi-Automatic (500 SA) operation and is equipped

with a standard, single phase, 208-230 V AC, 5.0 hp motor, and set-up

for 125/250 V AC input power supply. The Semi Automatic feature allows

the operator to preset the bending angle and once the bending angle is

reached, the unit will automatically return to the start position, ready

for the next bend.

This unit also includes remote electric foot

pedal controls, to help preset and stabilize the tube prior to engaging

the Semi-Automatic feature. Use the foot petals to bring the ram die

forward to put a small amount of pressure on the tube prior to starting

the Semi-Automatic operation or use the foot petals to bend to the

preset angle and when the angle is reached, the unit will automatically

return to the start position. The Semi-Automatic feature really helps

produce fast, repeatable bends.

Also available is the

EZEBEND™

Tube Bender 500 SA HS/XC - High Speed/Extra Capacity Bender with

Semi-Automatic operation. This bender is equipped with a larger single

phase, 208-230 V AC, 7.5 hp motor, and set-up for 125/250 V AC input

power supply. The larger motor and hydraulic system, allows for the

smooth bending of heavier gauge metal

without

having to maximize your system's working pressure. (When you increase

the system pressures, you increase the possibilities of leaks and system

breakdowns.)

The 25-ton working force, welded hydraulic

top cylinder is mounted to our standard, heavy-duty, ½'' thick wall

tube, which is thicker then our competitor's benders. This thicker

walled tube provides greater rigidity during each bending cycle, which

results in a more accurate bend. These bends are made with dies that are

machined out of steel, heat treat and hardened to prevent wear and give

the dies a very long working life. These are just a few of the many

examples of the quality components that we are proud to incorporate into

the products that we offer

Phone: (800) 873-0891 (216) 281-8585 Fax: (216) 281-8586

E-mail: info@ezebend.com Web Site: www.ezebend.com We accept Visa and MasterCard

Visit our other product line of PVC Bending Equipment and Accessories. Web Site: www.ezbend.com Email: pvcbend@ezbend.com